Atmospheric Management Systems

Encyclopaedia Entry - Life Support Technology

Atmospheric Management Systems encompass the diverse technologies employed to maintain breathable environments within space-based habitats, from emergency chemical processors to elaborate biological ecosystems. These systems represent the foundation of human survival beyond planetary atmospheres, enabling everything from short-term vessel operations to permanent colonisation of space-based installations. The technology spans from compact emergency systems suitable for smaller craft to comprehensive atmospheric ecosystems supporting populations in the tens of thousands.

Overview

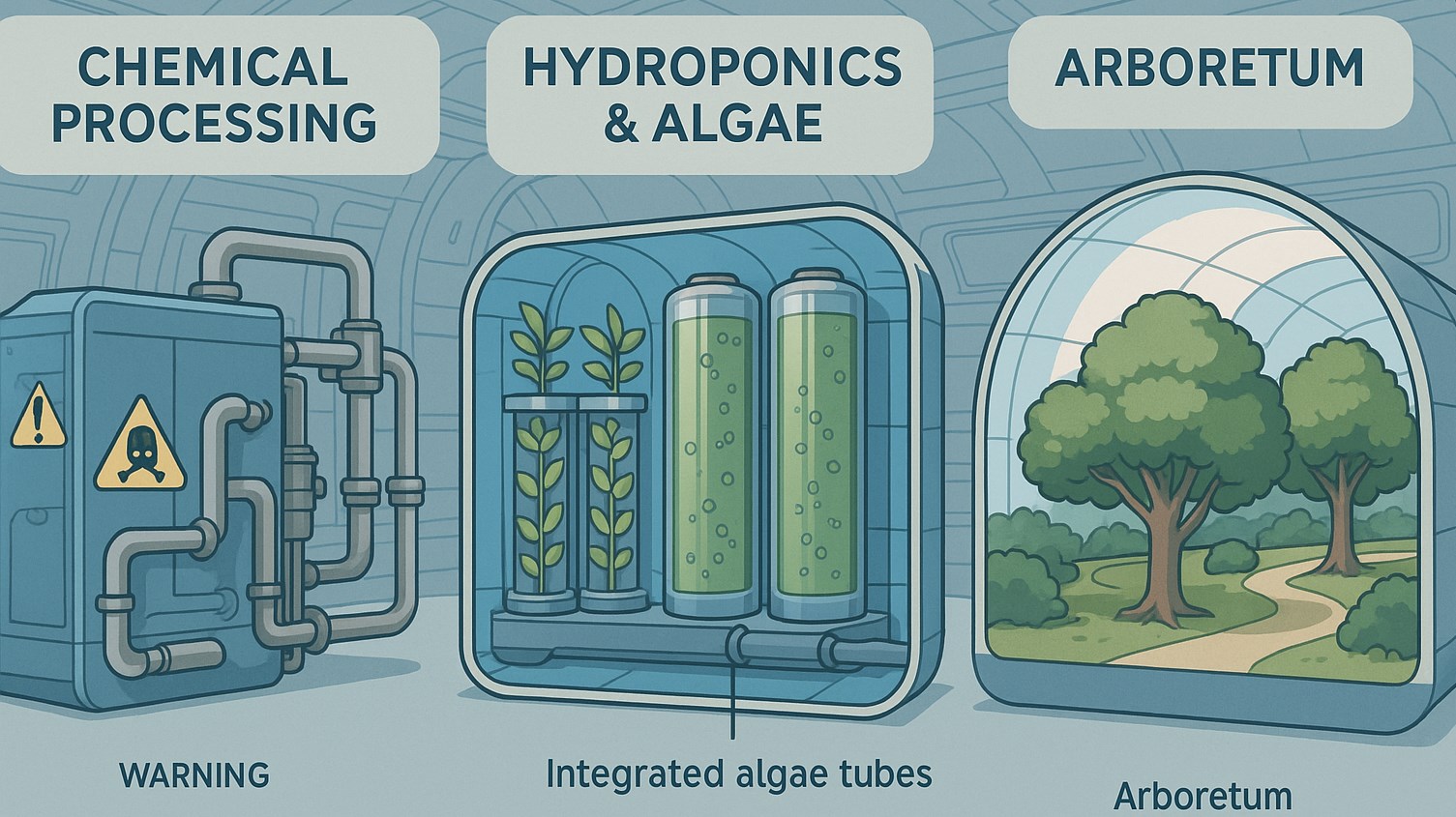

Human space habitation relies on three primary categories of atmospheric management: chemical processing systems, biological conversion systems, and hybrid installations that combine multiple approaches for optimal efficiency and redundancy. The selection of appropriate systems depends on factors including facility size, population, available resources, operational duration, and acceptable risk tolerance.

Chemical systems utilise synthetic compounds to rapidly convert atmospheric carbon dioxide into breathable oxygen, providing immediate life support with minimal space requirements. Biological systems employ living organisms—primarily algae and cultivated plants—to process atmospheric gases whilst simultaneously producing food resources. Larger installations typically implement comprehensive hybrid systems that maximise both efficiency and redundancy whilst providing enhanced quality of life for inhabitants.

Chemical Processing Systems

Aerozynex Technology

The most widely deployed chemical atmospheric processing system utilises Aerozynex, a synthetic compound developed in the late 21st century during humanity's initial expansion into interstellar space. This odourless chemical enables rapid conversion of carbon dioxide into breathable oxygen through highly efficient molecular processing.

Aerozynex systems require substantially less storage space than traditional oxygen tank installations, making them particularly valuable for space-constrained environments. The technology provides reliable atmospheric processing with minimal maintenance requirements, though the compound's extreme reactivity necessitates careful handling protocols and specialised storage systems.

Operational Characteristics

Aerozynex processors operate through direct chemical reaction with atmospheric carbon dioxide, stripping carbon atoms to release breathable oxygen. The process generates a distinctive stale odour that becomes characteristic of facilities relying primarily on chemical atmospheric processing. Whilst perfectly safe for human consumption, the processed air lacks the freshness associated with biologically generated atmospheres.

The compound's high reactivity enables exceptional processing efficiency but creates significant safety considerations. Improper handling or system failures can result in explosive decompression events that pose serious threats to personnel and facility integrity. These incidents, whilst typically undocumented for corporate liability reasons, have contributed to fatalities and substantial infrastructure damage across numerous installations.

Strategic Deployment

Chemical processing systems serve as the primary atmospheric management solution for remote installations with limited resources, such as mining colonies and research outposts. The technology also functions as emergency backup systems in larger facilities, automatically activating when primary biological systems experience failure or insufficient capacity.

Smaller vessels rely on basic air scrubbers and oxygen tanks for short-term operations, with regular replenishment required during extended missions. However, longer-range vessels and permanent installations require self-sustaining atmospheric processing capabilities that only chemical or biological systems can provide.

Biological Systems

Algae-Based Processing

Algae cultivation represents the most efficient biological approach to atmospheric management, providing maximum oxygen generation within minimal physical footprint. These systems require relatively low maintenance whilst delivering consistent atmospheric processing capabilities suitable for smaller installations and emergency situations.

Algae systems excel in space-constrained environments where traditional hydroponics cannot be accommodated. The organisms process carbon dioxide efficiently whilst producing breathable oxygen, though they lack the additional food production capabilities of more complex biological systems.

Hydroponic Systems

Hydroponic installations utilise cultivated plants to process atmospheric gases whilst simultaneously generating food crops for facility inhabitants. These systems require substantially more space than algae-based alternatives but provide significant advantages in terms of dietary variety and psychological well-being for long-term residents.

Due to less efficient atmospheric conversion rates compared to specialised algae systems, hydroponic installations often incorporate supplementary algae tanks to ensure adequate oxygen production. This hybrid approach maximises both atmospheric processing capacity and food production whilst maintaining acceptable space utilisation.

Advanced Biological Systems

The most sophisticated installations feature comprehensive biological ecosystems including arboretums and park-like environments that serve multiple functions simultaneously. These facilities provide superior air quality, food production, and recreational spaces that significantly enhance quality of life for permanent residents.

Arboretum installations represent the pinnacle of biological atmospheric management, creating Earth-like environments within space-based habitats. These systems support populations in the tens of thousands whilst providing psychological benefits that prove essential for long-term space habitation.

System Implementation Examples

Resource-Constrained Installations

Remote facilities such as the Alpha-7 Mining Colony rely exclusively on Aerozynex systems due to limited space, personnel, and financial resources. These installations prioritise immediate survival over comfort or long-term sustainability, accepting the distinctive air quality and safety risks associated with chemical processing.

Medium-Scale Operations

Medium-sized stations and the largest of vessels typically implement algae-based systems with Aerozynex backup capabilities. These installations utilise biological processing for normal operations whilst maintaining chemical backup systems for emergency situations.

Large-Scale Habitats

Massive installations including the Dyson Array and major orbital habitats implement comprehensive systems combining hydroponics, algae cultivation, and Aerozynex emergency backup. These facilities achieve optimal atmospheric quality whilst maintaining complete redundancy and food production capabilities.

Luxury Installations

The most advanced habitats feature full arboretum systems that create park-like environments within space-based facilities. These installations represent the highest standard of atmospheric management, providing Earth-quality air whilst serving as recreational and psychological support systems for permanent residents.

Corporate Control and Distribution

Atmospheric management technology deployment is subject to corporate monopolisation, with individual megacorporations controlling specific aspects of the supply chain. This control extends from Aerozynex manufacturing—where the precise formulation and production processes remain classified corporate intellectual property—to biological system implementation and maintenance.

The corporate stranglehold on atmospheric management technology creates dependency relationships that effectively bind space-based installations to ongoing corporate support. Facilities cannot achieve true independence whilst relying on proprietary atmospheric processing systems and consumable resources controlled by corporate interests.

Historical Development

Early Space Colonisation

Initial space colonisation efforts in the early 21st century relied primarily on biological systems utilising hydroponics and algae cultivation. These installations required substantial space allocation and ongoing maintenance but provided sustainable atmospheric processing without dependency on external supply chains.

Oxygen tank systems served as emergency backup during this period, though the storage space requirements and logistical complexity of regular replenishment made these systems impractical for permanent installations.

Chemical Processing Breakthrough

The development of Aerozynex technology toward the end of the 21st century revolutionised space-based atmospheric management by providing compact, efficient chemical processing capabilities. This breakthrough enabled the establishment of remote installations that would have been impossible using purely biological systems.

The technology proved particularly valuable for corporate expansion into remote systems where biological systems would be impractical or prohibitively expensive to implement and maintain.

Contemporary Integration

Modern atmospheric management represents the mature integration of chemical and biological systems, with installations selecting appropriate combinations based on operational requirements and available resources. The technology has evolved to provide reliable life support across the full spectrum of space-based facilities.

Safety Considerations

Chemical System Risks

Aerozynex systems require specialised safety protocols due to the compound's extreme reactivity and explosive potential. Improper handling procedures or system malfunctions can result in catastrophic failures that threaten facility integrity and personnel safety.

Corporate liability concerns have resulted in systematic underreporting of Aerozynex-related incidents, though industry personnel remain aware of the significant risks associated with chemical processing systems.

Biological System Vulnerabilities

Biological atmospheric processing systems face risks including contamination, disease, and system failure that can compromise atmospheric processing capabilities. However, these systems typically provide more gradual failure modes that allow time for corrective action or evacuation.

Redundancy Requirements

All permanent installations require multiple backup systems to ensure atmospheric integrity during primary system failures. The combination of biological primary systems with chemical backup capabilities represents current best practice for facility safety and operational continuity.

Current Status and Future Implications

Atmospheric management technology continues to evolve toward more efficient and reliable systems whilst maintaining corporate control over critical components and consumables. The integration of multiple system types provides enhanced capabilities and safety margins for space-based installations.

The dependency on corporate-controlled technology ensures that space-based facilities remain tied to established corporate supply chains and support networks. This relationship maintains corporate influence over space-based populations whilst providing reliable technological support for continued expansion and development.

Contemporary atmospheric management systems have achieved sufficient maturity and reliability to support permanent space-based civilisation on a scale previously impossible, enabling the establishment of major orbital habitats and industrial installations that form the foundation of humanity's expansion beyond Earth.